Wire Stripper Knowledge Guide

Wire Stripper Knowledge Guide

During the installation of photovoltaic cables, the most indispensable tool is the wire stripper

Everything you ever wanted to know about wire strippers is here, starting with the basics! Learn how this stripping equipment works, how to use it, and what varieties are on the market.

What are wire strippers for?

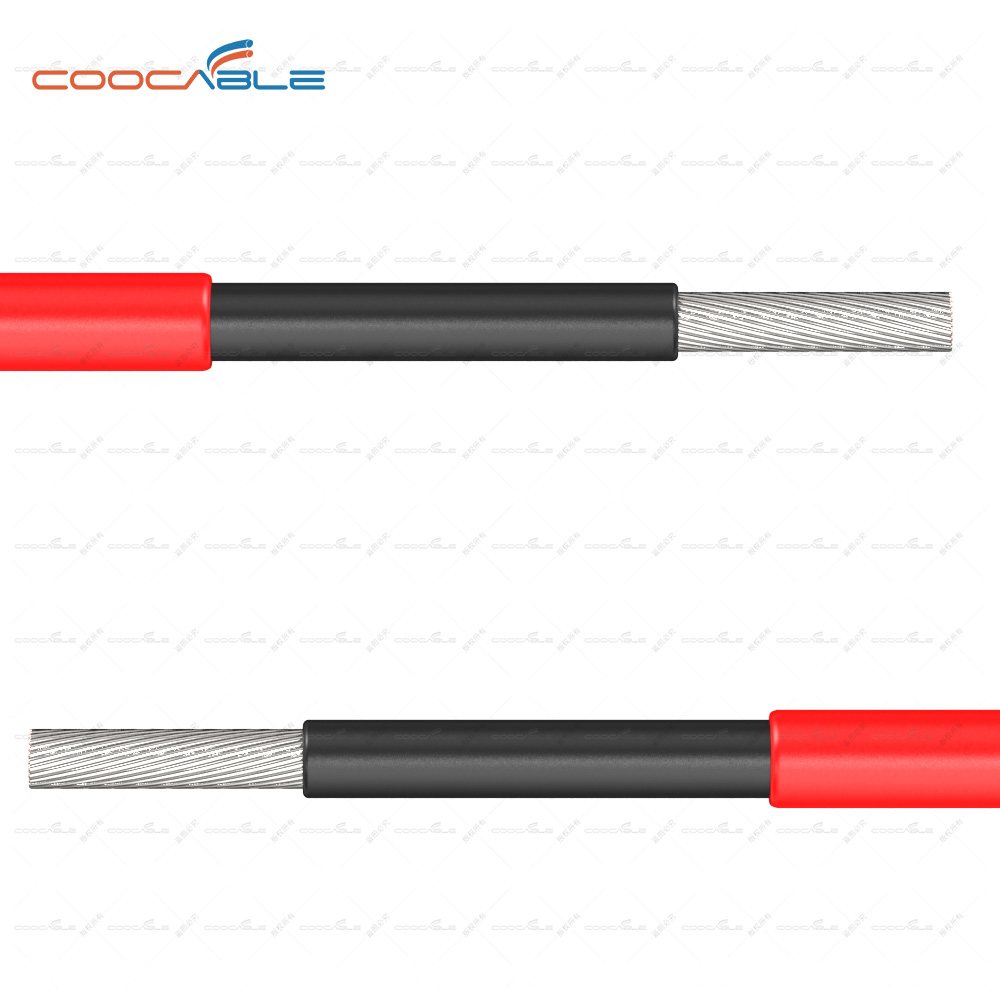

A wire stripper is similar to a pair of scissors or pliers. It can perform multiple tasks, but its main purpose is to strip insulation from the ends of wires.

In short, it's a hand-held tool for removing wire sheathing. Removing the sheath exposes the wires for repair or new use.

Stripping the end sections of the wires also allows for new connections to terminals and other wires. This is accomplished with a slotted cutting blade located in the jaws of the wire stripper.

The cut slots are sized to fit the various gauges of wire, not the insulation coating of the wire. The insulation is left behind as the wires pass through the slot.

Component

Wire strippers come in all shapes and sizes and are usually made of steel. Here are the basic parts:

·Crimpers for crimping connectors

·Ergonomic handle

· Voids used to create hooks or loops in wires from screw terminals

·Small bolt shears (usually 6/32 and 8/32)

· Tips/nose for holding, twisting, or forming hooks or loops in wires

·Various sizes of wire stripping slots

· Wire cutters

In addition, wire strippers usually have serrations for easy stripping. The handle can also be straight or curved, with a rubber coating for a secure grip.

No matter what form the tool takes, they have marked holes to match the wire gauge. Usually from 10th to 20th.

Some holes can match different gauges for different wire types. For example, the holes marked for 10-gauge solid wire can be the same as the holes for 12-gauge stranded wire. It is critical to make sure you are using the correct set of markers for the type of wire you are cutting.

How to use a wire stripper

The stripping process is the same for each tool type. The following steps should work no matter what version you are using.

Step 1: Determine Wire Gauge and Type

Determine the gauge of wire you need to strip. Look for the outermost jacket that binds the wires together inside the NM cable. NM stands for non-metallic sheathed cable.

Let's say the number is 12/2. The first number is the wire gauge - in this case 12. Also, it's worth noting whether the wire is solid or stranded copper.

STEP 2: MATCH WIRE TO TOOL

Match the wire gauge to the correctly marked hole on the wire stripper. You have to be extra careful with this.

Choosing a hole that is too large means you will have a hard time peeling the insulation off. Conversely, a hole that is too small can result in the wire being scratched or completely damaged.

Step 3: Open the Wire Strippers and Secure the Wires

Open the wire stripper handle and "pin" the wire to one side of the appropriate hole. Gently press the handles together until they cannot be pushed any further. This will cut the insulation on the wire.

Step 4: Twist Tool If Necessary

If the wire insulation is not completely cut, slowly rotate the wire inside the hole. Alternatively, wire strippers around the wires.

Rotate a quarter turn in one direction, then return.

Step 5: Strip Insulation

Pull the wire strippers toward the cut end of the wire to remove the insulation. Push the tool with the thumb that holds the wire. Hold the handle firmly with the other hand.

Features to Look for in a Wire Stripper

So, what exactly makes a good pair of wire strippers? When looking for the best tool, you want one that is easy to use, powerful and reliable.

There are some features to consider to make your investment worthwhile and certainly fit your needs.

Grip

A comfortable-grip wire stripper is a very easy tool to use. You'll want a high-quality handle so you can peel off the insulation without hurting your hands.

Highly recommend those with rubber grips.

Guaranteed ease of use

Aside from a good grip, the right wire strippers should make the job easier! Unlike improvisation with a knife, the process had to be painless.

With this, you can choose between automatic or manual types. Automatic strippers are the easiest to use, while manual strippers require more effort.

However, if you want more precision with thinner wires, opt for manual wire strippers.

promise safety

As with any electrical work, safety is a must. So you need a good pair of strippers to keep you safe.

Look for a unit that offers good stability and control while in use. Of course, you need to be confident in using the tool and handling the task.

It also helps to read the instructions before starting!

with the correct precision

Top quality wire strippers for optimum precision. Please make sure the blade of the wire stripper is working properly before use.

Versatile quality

Most wire strippers double as wire cutting tools. If you also often need to cut wires, it's a good idea to use a multi-purpose wire stripper.

Other features to consider:

· Clear wire gauge marking

·Handle return spring

·Locking handles, especially for spring models, so they don't get dull in the toolbox

·Vibrant colors help prevent loss

There is also a tool bag for this wire stripper, if you are interested in these tubes, please feel free to contact us.