4mm solar panel cable related introduction

What is solar panel cable

Solar panel cable is the core component of the photovoltaic power generation system. It connects the entire photovoltaic system and transfers the current from the solar panel to the inverter, converts the AC current to the DC current and stores it in the battery to complete the energy conversion.

In photovoltaic lines, 4mm and 6mm are the most common sizes, and the largest can be produced up to 100mm.

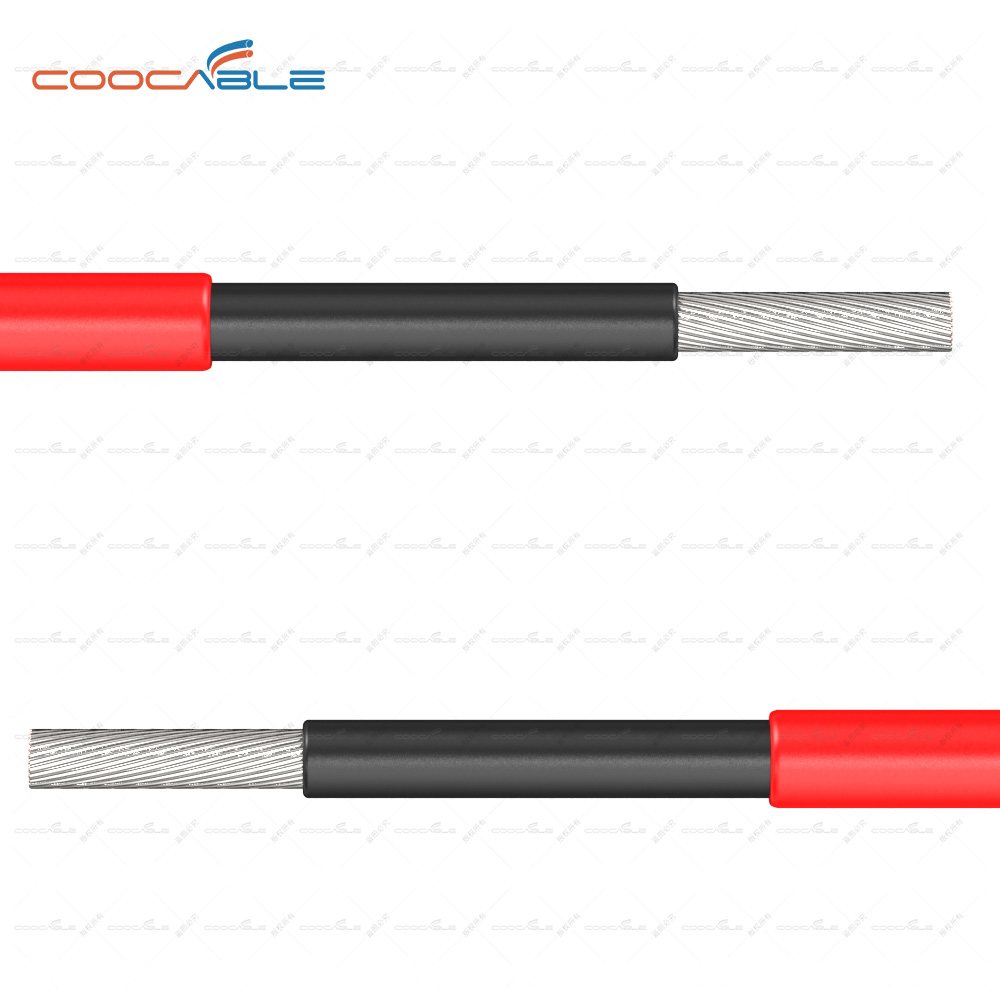

Among them, the conductor is made of tinned copper. The material of tinned copper wire can be soft, has good electrical conductivity, and greatly prolongs the service life of weak wires. The sheath is usually made of low-smoke, halogen-free, flame-retardant and environmentally friendly materials. It has the advantages of high temperature resistance, ozone resistance, ultraviolet resistance, water vapor resistance, anti-microbial resistance, strong short-term overload capacity, long life, wear resistance, oil resistance, corrosion resistance, high tensile strength, etc. It can be widely used in solar power plants, photovoltaic systems and other fields.

Available in single-core and double-core sizes, if you plan to connect a 4mm twin-core solar cable, you will usually need to connect the positive and negative wires from the string directly to the solar inverter (sometimes called a "generator box") . The power output of the component figures out the wires you need. 4mm cable is used, while other popular variants such as 6mm solar cable and 2.5mm solar wire are readily available according to your needs. 4mm solar cable TVs are mainly used outdoors in strong sunlight, which means many of them are UV resistant. To avoid short circuits, experts need to make sure they don't connect the positive and negative wires on the exact same cable. Therefore, the sheath color is usually black and red to distinguish the positive and negative electrodes.

Single-core cables usually refer to one conductor corresponding to one insulating layer, Even single wires are useful and can also give high dependability. In terms of color, you generally have a red (electricity transportation) and blue (unfavorable charge) wire

From the perspective of installation and maintenance, multi-core photovoltaic cables will have certain advantages in laying efficiency and convenience, because the cables have inner layers and multi-layer double-layer protection, which is safer

The difference between photovoltaic wire and ordinary wire

Differences in usage requirements:

1. Different rated voltage

Photovoltaic cable: 600/100V or the new standard 1000/1500V;

Ordinary cable: 300/500V or 450/750V or 600/1000V (YJV/VV series)

2. Different adaptability to the environment

Photovoltaic cable: It needs to be resistant to high temperature, cold, oil, acid, alkali and salt, rain, UV, flame retardant, and environmental protection. It can be used in harsh climates with a service life of more than 25 years.

Ordinary cable: It is generally used for indoor laying, buried pipe and electrical equipment connection, etc. It has certain temperature and oil resistance, but cannot be exposed outdoors or in harsh environments. The service life is generally based on the actual situation, and there are no special requirements. .

The difference between raw materials and processing technology

1, the raw materials are different Photovoltaic cable:

Conductor: Tinned copper wire conductor

Insulation: Cross-linked polyolefin insulation

Sheath: Cross-linked polyolefin insulation Ordinary cable:

Conductor: copper conductor

Insulation: PVC or PE insulation

Sheath: PVC sheath

Different processing technology

Photovoltaic cable: the outer skin is cross-linked and irradiated

Ordinary cables: generally do not undergo cross-linking irradiation, YJV\YJY series power cables will be cross-linked

Authentication is different

Photovoltaic cables generally require TUV certification, while ordinary cables generally require CCC certification or only require a production license