The harm of unqualified solar cable PV wire insulation jacket

Photovoltaic cables are a large category of electrical products used to transmit electricity, transmit information and realize electromagnetic energy conversion. Cables play an important role in all economic activities and social life. It can be said that where people are, where there is production, transportation, and all economic activities, cables are inseparable from cables, so the quality of cables directly affects our lives. The main problems with non-conforming products are the construction of the jacket before aging, conductor size, conductor resistance, insulation and tensile strength. Consumers using such products are prone to the risk of electric leakage, electric shock and even fire. These inferior products have buried many hidden dangers in the normal operation of the power system.

1. After a single-phase grounding (short-circuit) accident occurs in the cable, the relay protection device does not act and cuts off the fault, causing the wire and cable to overheat and cause the insulation layer to catch fire.

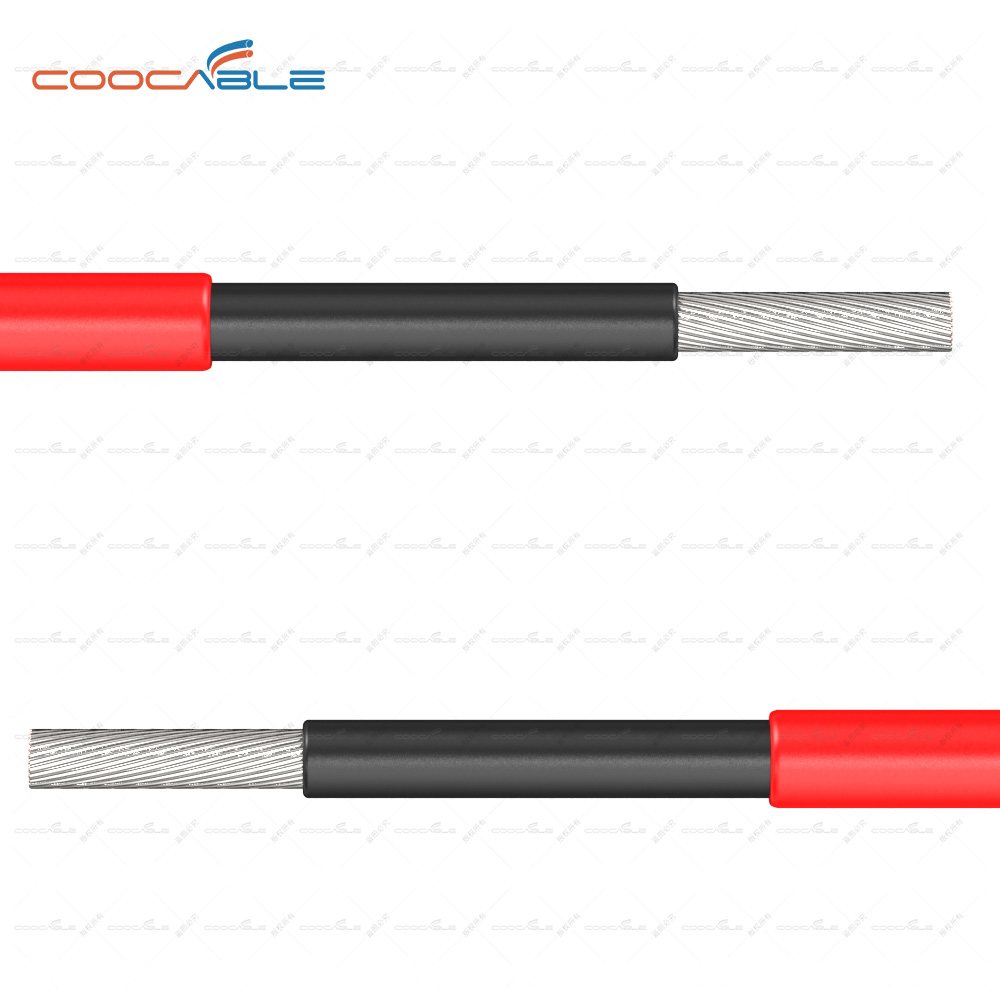

2. Wire and cable with qualified insulation tensile strength and elongation before aging. The tensile strength and elongation of the insulating sheath before aging are unqualified, which directly greatly shortens the service life of the cable, and the insulator is easily broken during the construction process or in the environment of high temperature and long-term energization, resulting in the conductor being exposed. Risk of electric shock and short circuit.

3. Wires with unqualified conductor resistance. Conductor resistance is mainly an important indicator to evaluate whether the conductor material and cross-section of the wire and cable are in compliance. When the conductor resistance exceeds the standard, the loss of the current passing through the line increases, and the heating of the wire and cable increases. The main reason for the unqualified conductor resistance is that, in order to reduce the cost, the company shrinks the copper material, which accounts for 80% of the raw material cost, either reducing the cross-sectional area of the conductor or using too much impurities in the recycled copper, resulting in serious conductor resistance of the wire and cable. . Exceeding the standard will not only cause fire during use, but also accelerate the aging of the insulating layer covering the wire. Volt cables are mainly insulated by the outer layer of the sheath, they are corroded by the outside air for a long time, the insulation performance gradually declines, gradually ages and hardens, becomes brittle or falls off. At this point, they can no longer provide insulation, especially in wet weather, and although the appearance of the wire is intact, the insulation performance is reduced. When moisture penetrates metal conductors, a short circuit can occur and cause a fire, and every year, there are countless fire incidents caused by cable short circuits around the world.