Basic principles of solar photovoltaic cable selection

Basic principles of cable selection

The cable selection of photovoltaic power generation follows the general requirements of cable selection, that is, the type is selected according to the voltage level, the allowable current for continuous operation, the short-circuit thermal stability, the allowable voltage drop, the economic current density and the environmental conditions for laying.

At the same time, photovoltaic power generation has its own characteristics, and solar energy systems are often used in harsh environmental conditions, such as high temperature, severe cold and ultraviolet radiation.

Therefore, the selection of cables in photovoltaic systems should consider the following factors:

(1) Insulation performance of the cable;

(2) Heat resistance and flame retardant properties of the cable;

(3) Moisture-proof and light-proof (anti-radiation) of the cable;

(4) The laying method of the cable;

(5) The material of the cable conductor (copper core, aluminum alloy core);

(6) Specification of cable cross section.

2 Selection of cables

2.1 Types of photovoltaic power generation cables

Photovoltaic power generation system cables can be divided into DC cables and AC cables according to the photovoltaic power generation system. Among them, the cables in series between components and the DC cables in parallel between groups and strings account for more than half of the cables. The cables used after the inverter are AC cable.

According to different application environments, the cables of photovoltaic power generation systems can be divided into:

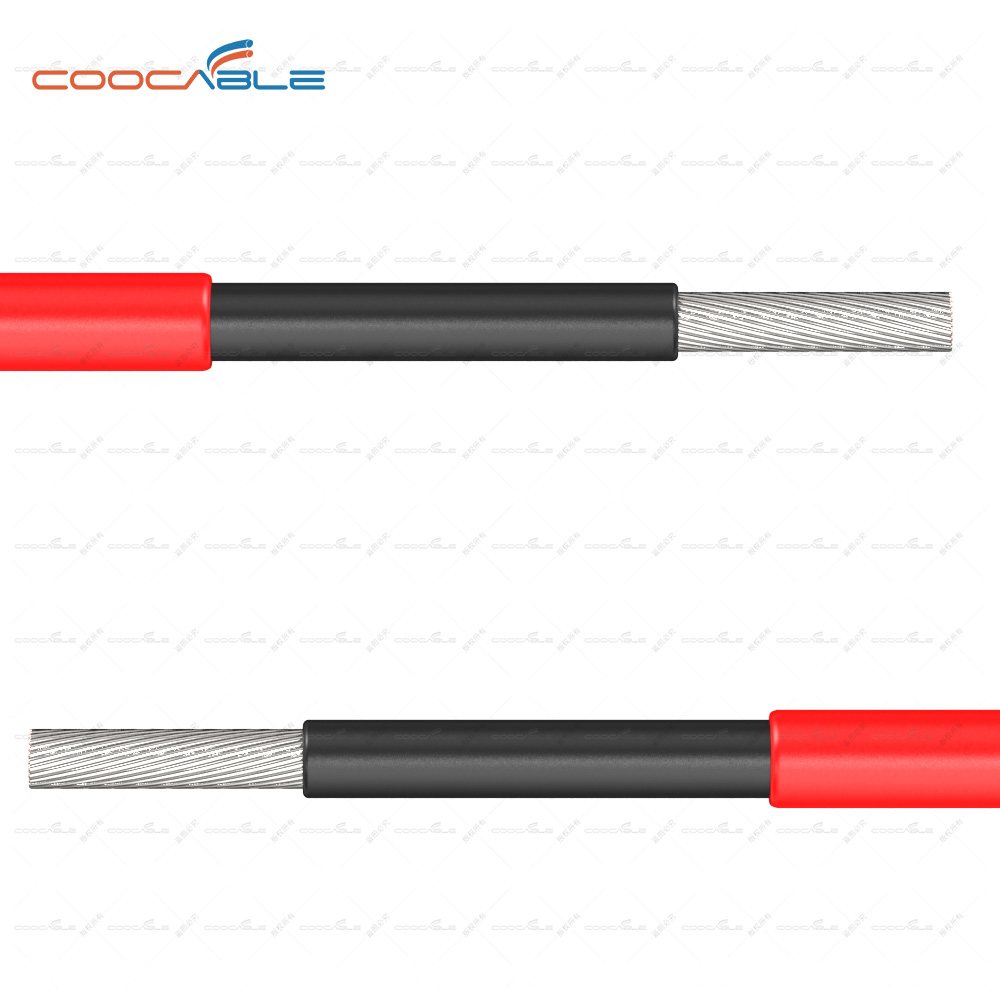

1. DC cable

(1) The series cable between modules and modules, this part should use special cables with photovoltaic certification.

(2) For the parallel cables between the strings and between the strings and the DC distribution box (combiner box), rare earth aluminum alloy conductor cables can be selected.

(3) For the cable between the DC distribution box and the inverter, rare earth aluminum alloy conductor cable can also be used for this part.

The above cables are all DC cables, which are laid outdoors a lot. They need to be moisture-proof, sun-proof, cold-resistant, heat-resistant, and UV-resistant. In some special environments, they also need to be resistant to chemicals such as acid and alkali. The connecting cables between the components are usually supplied in sets with the components.

2. AC cable

(1) The connecting cable from the inverter to the step-up transformer.

(2) The connecting cable from the step-up transformer to the power distribution device.

(3) The connection cable from the power distribution device to the power grid or the user.

This article focuses on the selection and laying of DC cables in photovoltaic grid-connected power generation, and its principles are also applicable to some other types of photovoltaic power generation projects.

2.2 Photovoltaic special cable

A large number of DC cables in the photovoltaic power generation system need to be laid outdoors, and the environmental conditions are harsh. The cable material should be determined according to the resistance to ultraviolet rays, ozone, severe temperature changes and chemical erosion. The long-term use of ordinary material cables in this environment will cause the cable sheath to be fragile, and even decompose the cable insulation. These conditions will directly damage the cable system, and also increase the risk of short-circuiting the cable. In the medium and long term, the possibility of fire or personal injury is also higher, which greatly affects the service life of the system.

For the above reasons, it is very necessary to use photovoltaic special cables and components in solar energy systems. With the continuous development of the photovoltaic industry, the photovoltaic accessories market has gradually formed. As far as cables are concerned, photovoltaic professional cable products of various specifications have been developed.