All you need to know about 4mm 2 core solar cable

All you need to know about 4mm 2 core solar cable

product description

Solar photovoltaic power generation is a green, clean and environmentally friendly renewable energy. Now most countries in the world have begun to adopt photovoltaic power generation, and a large number of photovoltaic power stations have been built, and photovoltaic lines are an indispensable part of it. In the past, most of the photovoltaic lines used a single-core structure, but after installation and laying, the positive and negative electrodes were suspended and separated under the solar panel, which looked messy and affected the appearance. On this basis, a two-core detachable photovoltaic cable - 2 core solar cable is developed

performance requirements

Solar systems and other photovoltaic modules are mostly installed in harsh environments, and suffer from high temperature, low temperature, freezing damage, long-term ultraviolet radiation and corrosion all year round. Coocable 4mm 2core solar cable have the following properties, which can effectively resist harsh environments

Ambient Temperature : -40°C up to 90°C, Max Temp at conductor +120°C

Insulation Resistance At 20℃: ≥ 100 0 MΩ.km

Voltage Rating: AC : 1000V ; DC : Max.1800 V

Current carrying capacity AT 60℃: 55A

Excellent ozone resistance, UV resistance, humidity and heat resistance, acid and alkali resistance, and dent resist ance.Halogen-free flame retardant, service life not less than 30 years

ance.Halogen-free flame retardant, service life not less than 30 years

International TUV double certification, effective quality assurance

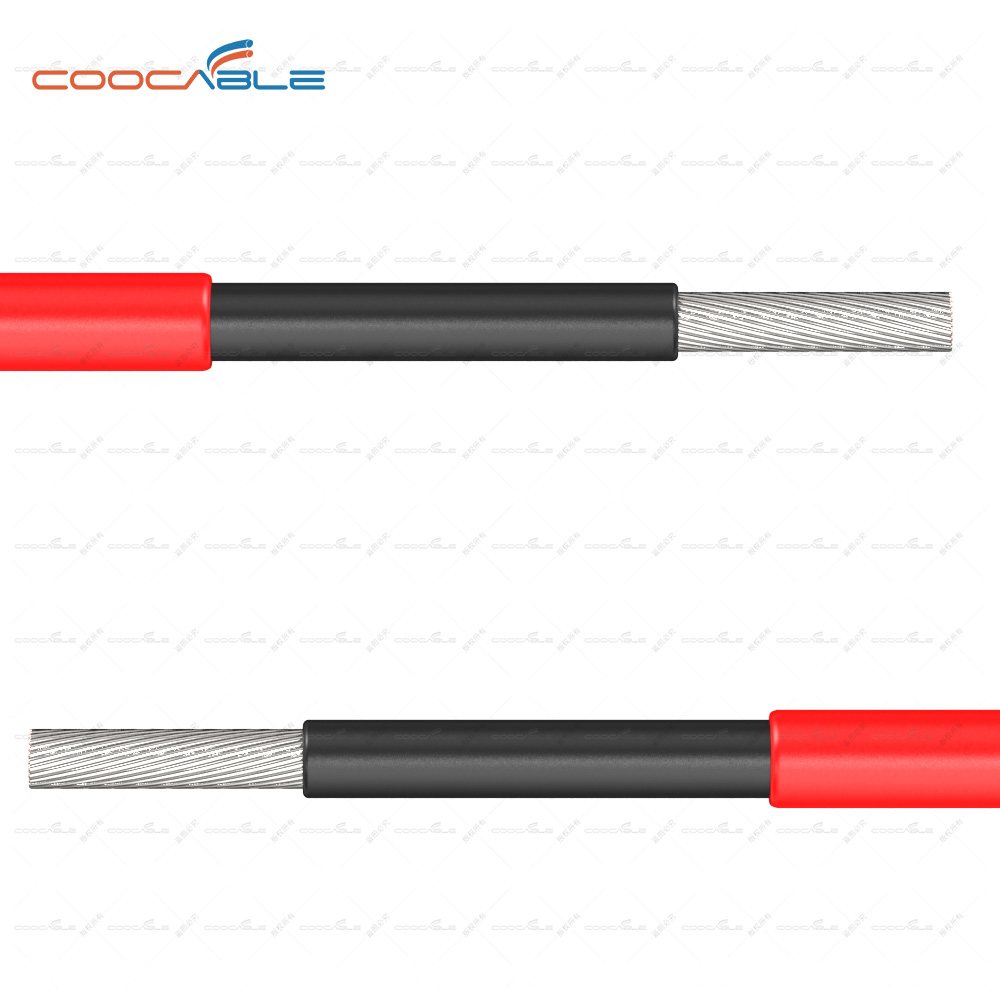

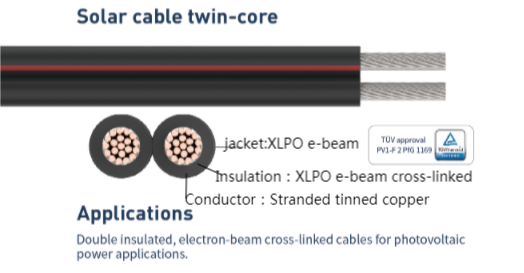

product structure

Conductor: Tinned fine copper strands acc.to VDE0295/IEC 60228, Class 5.Insulation:XLPO, flame retardant, halogen free

electron-beam cross-linked.Jacket: XLPO, flame retardant, halogen free, electron-beam cross-linked.

Insulation color :black

Jacket color :black or red

Process requirements

Process flow: stranding of tinned copper conductors—extrusion insulation—coating talcum powder on the surface of two-core insulation—irradiation. The last step of irradiation is very important. After irradiation, the comprehensive physical properties of voltaic cables have been greatly improved, and the cables’ UV resistance UV (anti-sun) performance and flame retardant effect have been greatly improved, and the cable's anti-hydrolysis ability (rain, fog, dew, etc.) and acid and alkali resistance (common acid rain corrosion) have been reinforced and improved, so The process of photovoltaic cable irradiation cannot be omitted. It is a necessary link for sustainable, long-term and stable use, but some manufacturers reduce this crucial link in order to reduce costs. Everyone must pay attention to this when purchasing photovoltaic cables.

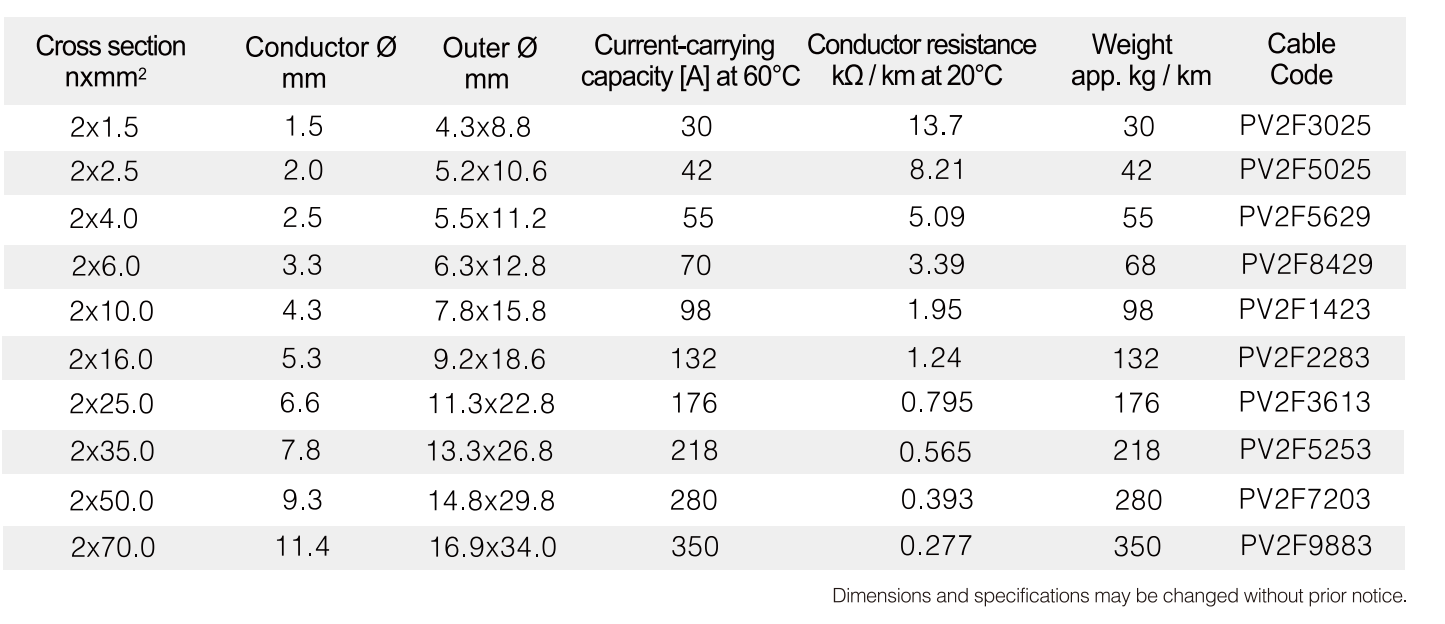

Product parameters