6mm solar special cable structure requirements and use characteristics

The cable can be a single-core sheathed structure (DC cable) or a multi-core sheathed structure (2~5 cores, AC cable). #solar cable#

Structural Requirements:

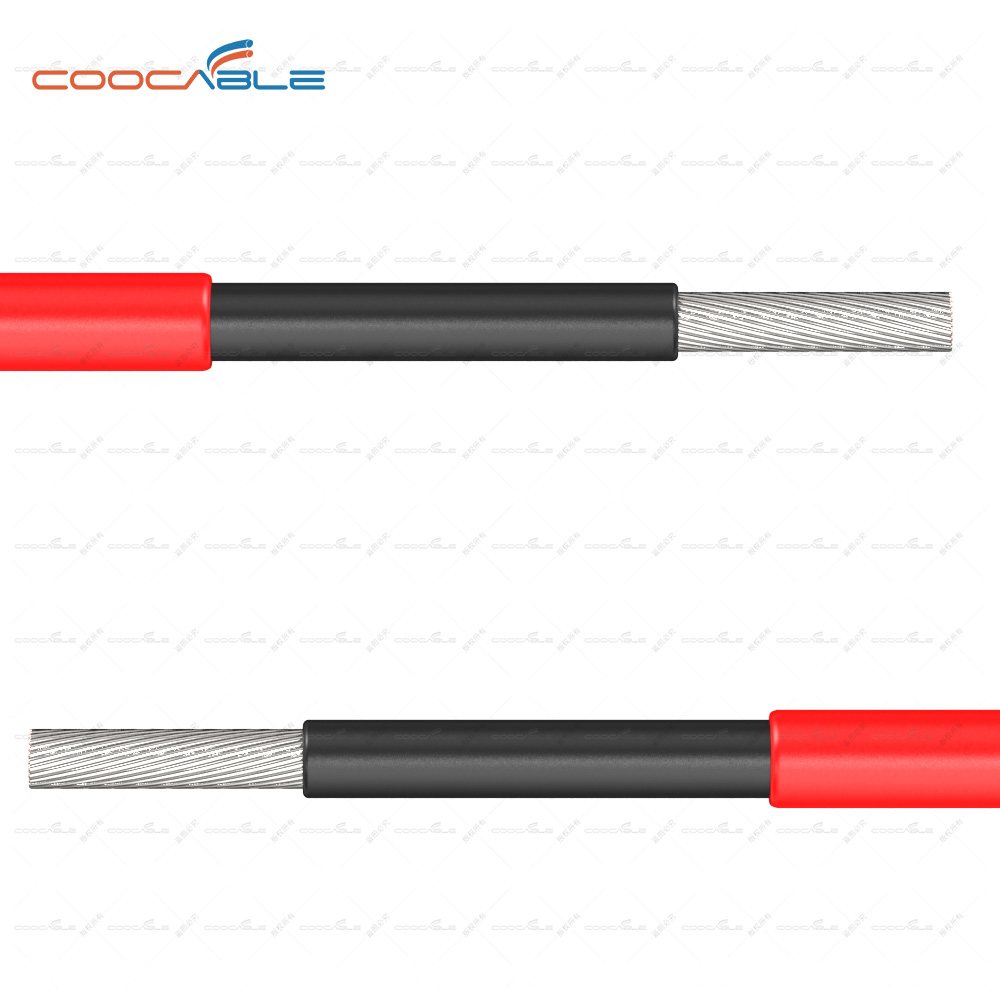

Conductor: The conductor material is annealed soft copper wire, which can be tinned or not. The conductor surface should be smooth, free of oil, burrs that damage insulation, and raised or broken single wires. Insulation layer: The insulating surface is flat, uniform in color, and there is no visible blistering impurities on the cross-section. It should be tightly wrapped on the conductor, and should be easily peeled off without damaging the conductor or the tin-plated layer. Single-core cable insulation core black is the preferred color.

Sheath: The sheath should be extruded and include one or more adjacent adhesion layers, the sheath should remain smooth and not less than 0.5mm thick.

Use features:

In normal operation, the maximum continuous working temperature allowed by the conductor when the cable is in normal use is 120°C;

The ambient temperature suitable for the cable is - 40 ~ 90 ℃;

The expected service life of the cable product is 25 years;

Extremely high environmental adaptability (acid resistance, alkali resistance, sunlight resistance, radiation resistance and other special properties);

Environmentally friendly flame retardant properties (halogen-free properties, etc.) under special conditions. (Some cable manufacturers usually add halogen-based flame retardants to the cable material in order to improve the flame retardant performance of the cable, but this flame retardant cable material will generate a lot of smoke and hydrogen halide gas when it burns, which will suffocate people. And death, seriously endanger people's lives, the EU has explicitly banned the use of flame retardant cables containing halogen.)