Pv1-f pv cable and ordinary cable difference

Photovoltaic cables are constantly exposed to sunlight, and solar systems are often used under harsh environmental conditions, such as high temperatures and ultraviolet radiation. In Europe, sunny days will result in on-site temperatures of up to 100°C for solar systems. At present, we can use a variety of materials including PVC, rubber, TPE and high-quality cross-linking materials, but unfortunately, rubber cables rated at 90°C, and even PVC cables rated at 70°C are often used outdoors. At present, the national Golden Solar project is frequently launched, and many contractors in order to save costs, Do not choose the solar system dedicated cable, but choose ordinary PVC cable to replace the photovoltaic cable, obviously, this will greatly affect the service life of the system.

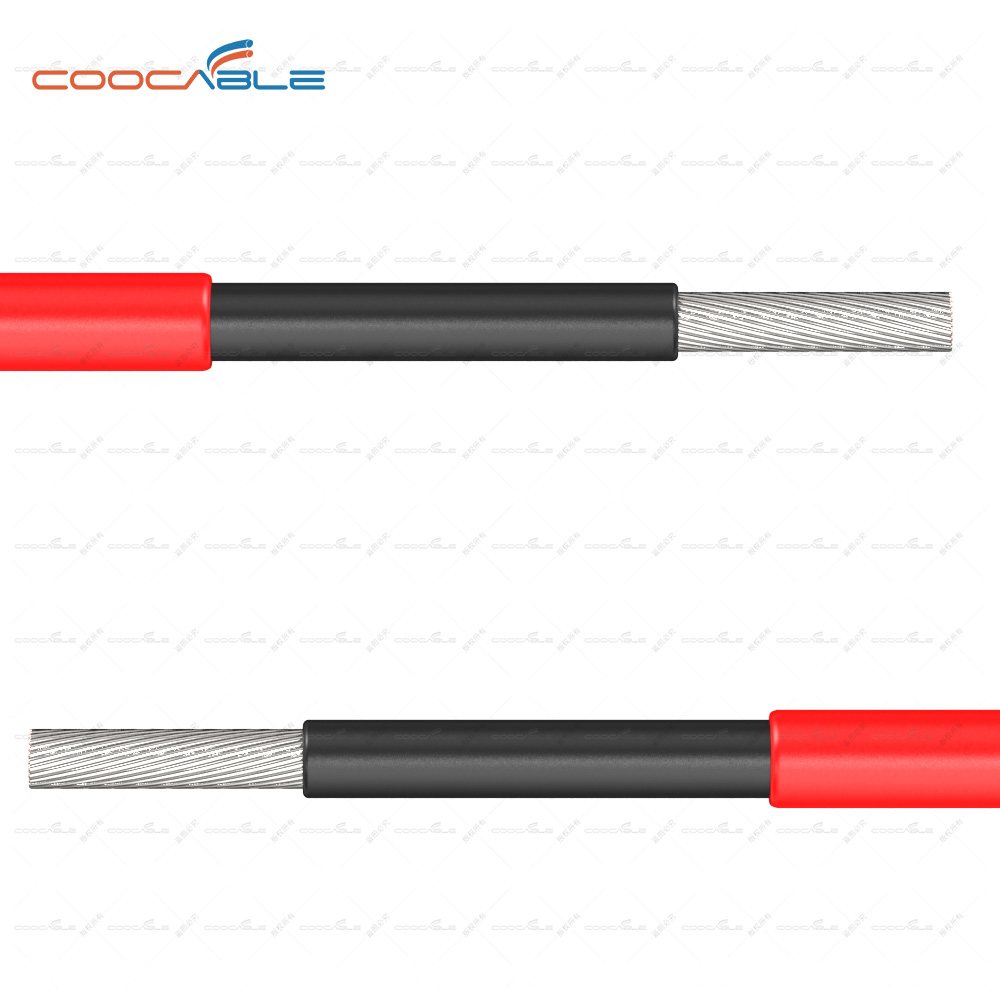

Pv1-f photovoltaic cable is determined by its cable special insulation material and sheath material, we call it crosslinked PE, after irradiation accelerator, the molecular structure of cable material will change, so as to provide its performance. Resistance to mechanical loads In practice, cables can be routed on sharp edges of the roof structure during installation and maintenance, while the cables are subjected to stress, bending, tension, cross-tensile loads and strong impact. If the cable sheath is not strong enough, the insulation layer of the cable will be seriously damaged, which will affect the service life of the cable, or lead to short circuit, fire and human injury hazard.