Performance requirements for DC Solar Cable

As the use environment of photovoltaic power plants becomes more and more complex, there are more and more requirements for solar cables, so what performance does the solar cable need to meet?

1. Requirements for high and low temperature characteristics

Withstand low temperature: the winter temperature in the western and northern regions is relatively low, and the low temperature in extreme areas can reach -40 ℃ below zero. This requires the cable and good low temperature resistance.

Withstand high temperature: the surface temperature in the eastern and southern regions can easily reach above +70°C, and the extreme temperature in areas with poor heat dissipation is likely to exceed +90°C. This requires that the material temperature of the cable can meet the requirements of the power station to work in extreme temperatures.

2. Requirements for anti-humidity and heat characteristics

Application environment: Many power stations in the fish-optical hybrid project are directly built on fish ponds or water surfaces, requiring cables to work normally in a humid environment for a long time.

Frequent changes in temperature and humidity have a direct effect on the insulation and ageing of the sheathing of the material.

Special requirements: Considering the influence factors of damp and hot environment on the aging performance of insulation and sheath materials, the selected insulation and sheath materials are at a temperature of +90 ℃ and a humidity of 85%.

3. Resistance to sunlight and ultraviolet rays

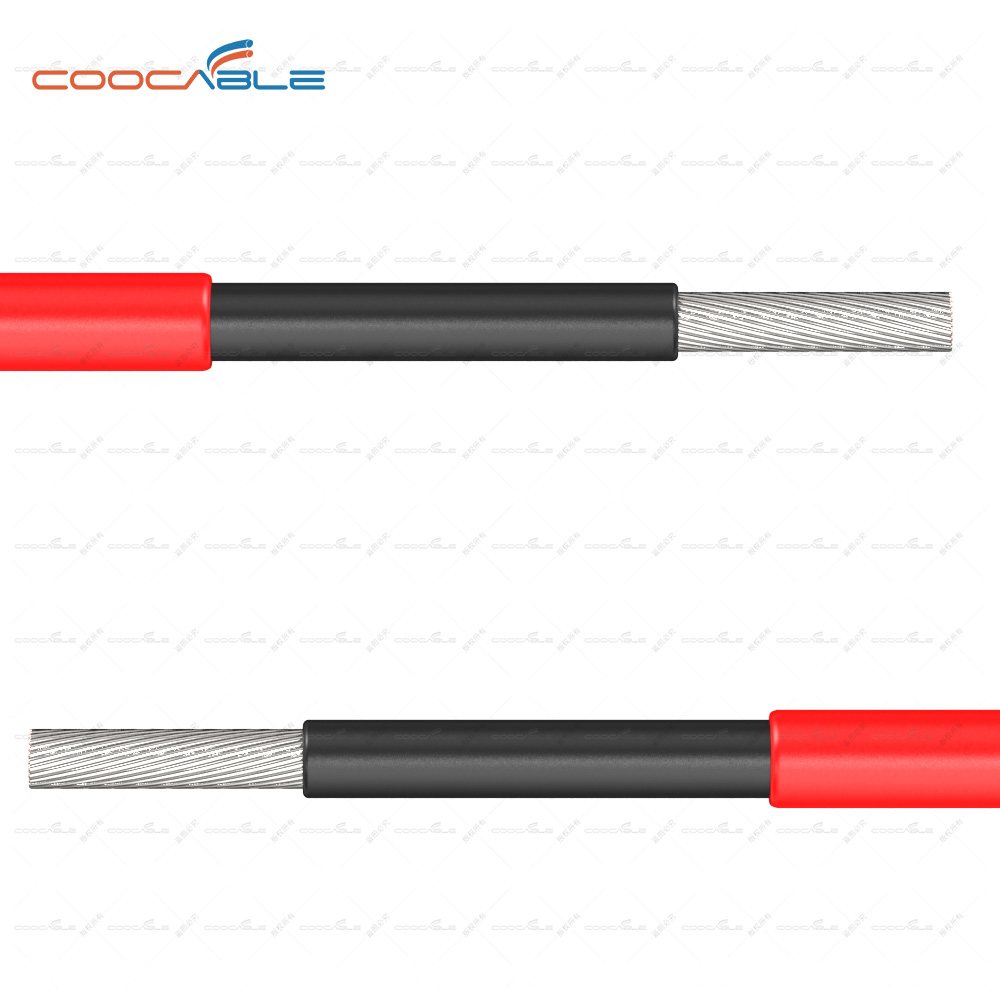

Requirements: Many cables of photovoltaic power plants are laid bare. In most cases, cables from solar modules to combiner boxes and even to inverters are laid directly and bare. This requires that cables must be able to withstand sunlight and ultraviolet radiation. It can work normally for a long time under the vertical radiation of sunlight and ultraviolet rays.

Four. Requirements for resistance to ozone corrosion

The power station is installed in an area with high ozone content. Ozone has a certain corrosive effect on the cable sheath, that is, it accelerates the aging of the sheath and affects the use of the cable.