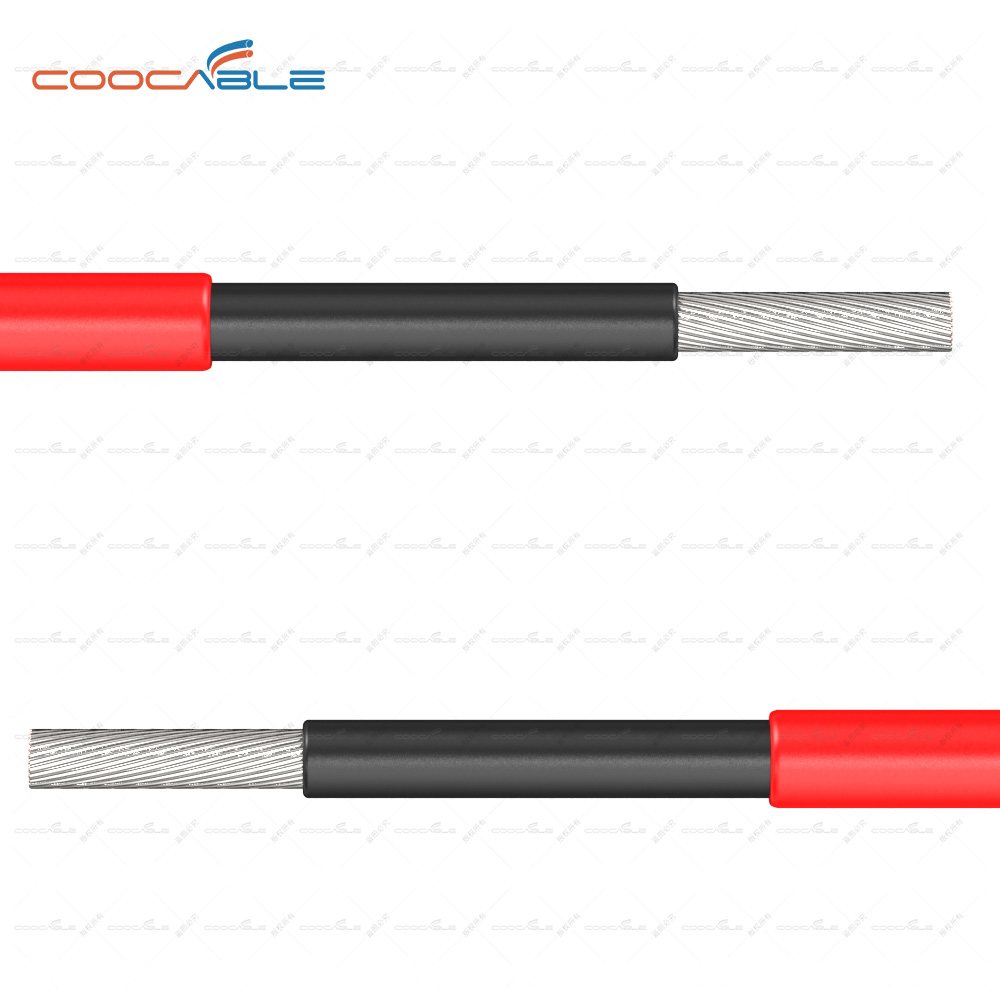

Introduction of insulation layer and sheath of 6mm² DC solar cable

The solar cable is often in a harsh environment. The cable may be in the soil below the ground, in the rocks overgrown with weeds, exposed to the sun for a long time, and withstand the impact of external forces such as ultraviolet temperature difference between day and night, humidity and so on. If the strength of the solar cable sheath is not enough, the power insulation layer will be damaged, which will affect the service life of the entire cable, or short-circuit, fire and other dangerous problems will occur.

Therefore, the solar cable is usually made of polyvinyl chloride, which is also PVC. Traditional PVC material has the characteristics of non-flammability, high strength, weather resistance and excellent geometric stability, strong resistance to oxidants, reducing agents and strong acids, and excellent electrical insulation properties.

In some relatively excellent cable manufacturers, additional radiation treatment will be added. The radiation cross-linked material has higher mechanical strength than before radiation treatment. The radiation process changes the chemical structure of the polymer of the cable insulation sheath material, which can melt The conversion of non-fusible thermoplastic materials to non-fusible elastomeric materials and the cross-link radiation significantly improve the thermal, mechanical and chemical properties of cable insulation. Rodent repellent can also be added to the insulation layer of the sheath to protect the cable from being bitten by animals such as insects and ants.